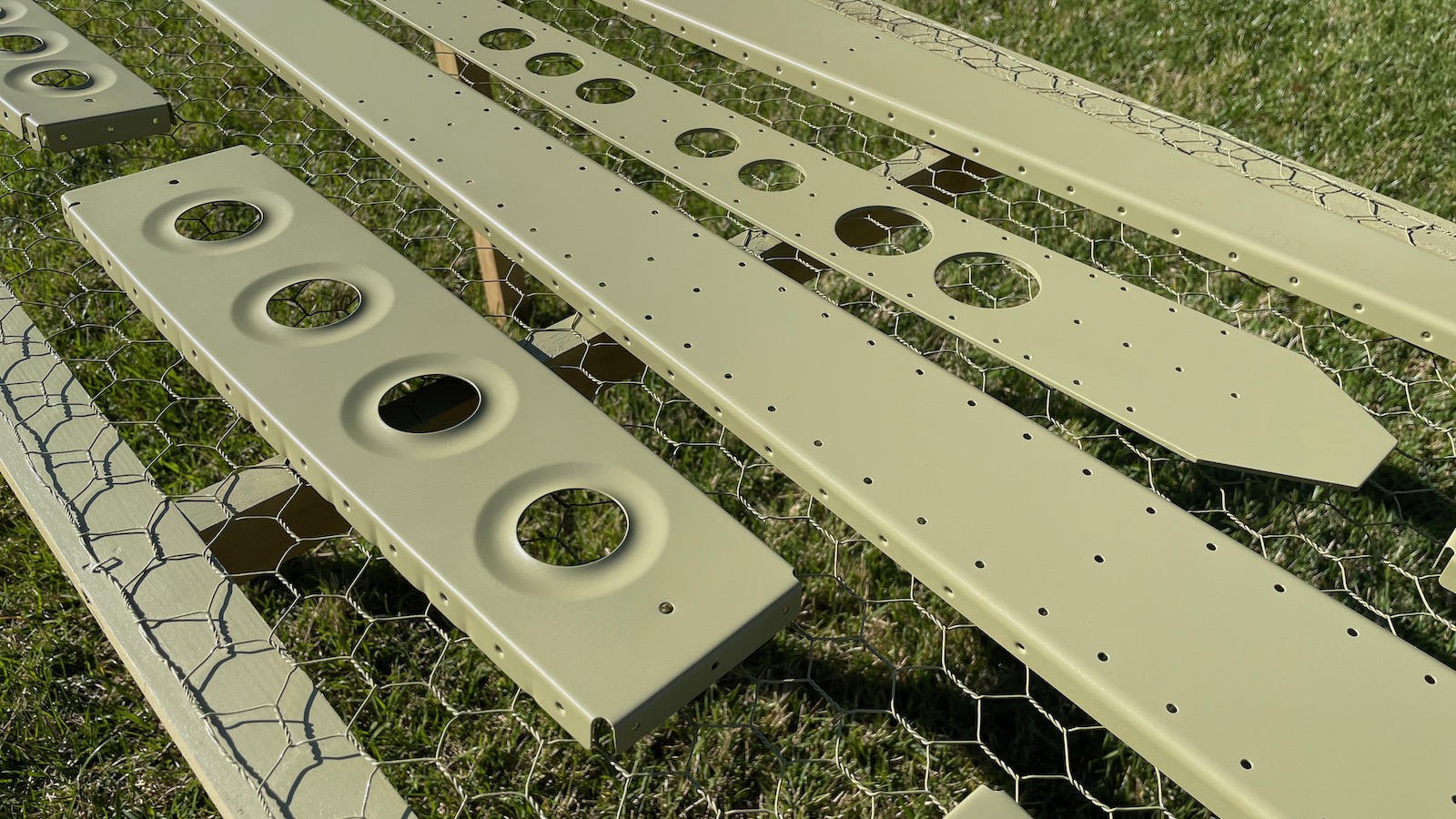

Having finished match drilling, deburring, dimpling and prepping the vertical stabilizer pieces, it’s time to prime them. I brought the compressor home and set up in the backyard again as before, laying out the pieces on the chicken wire paint table I made.

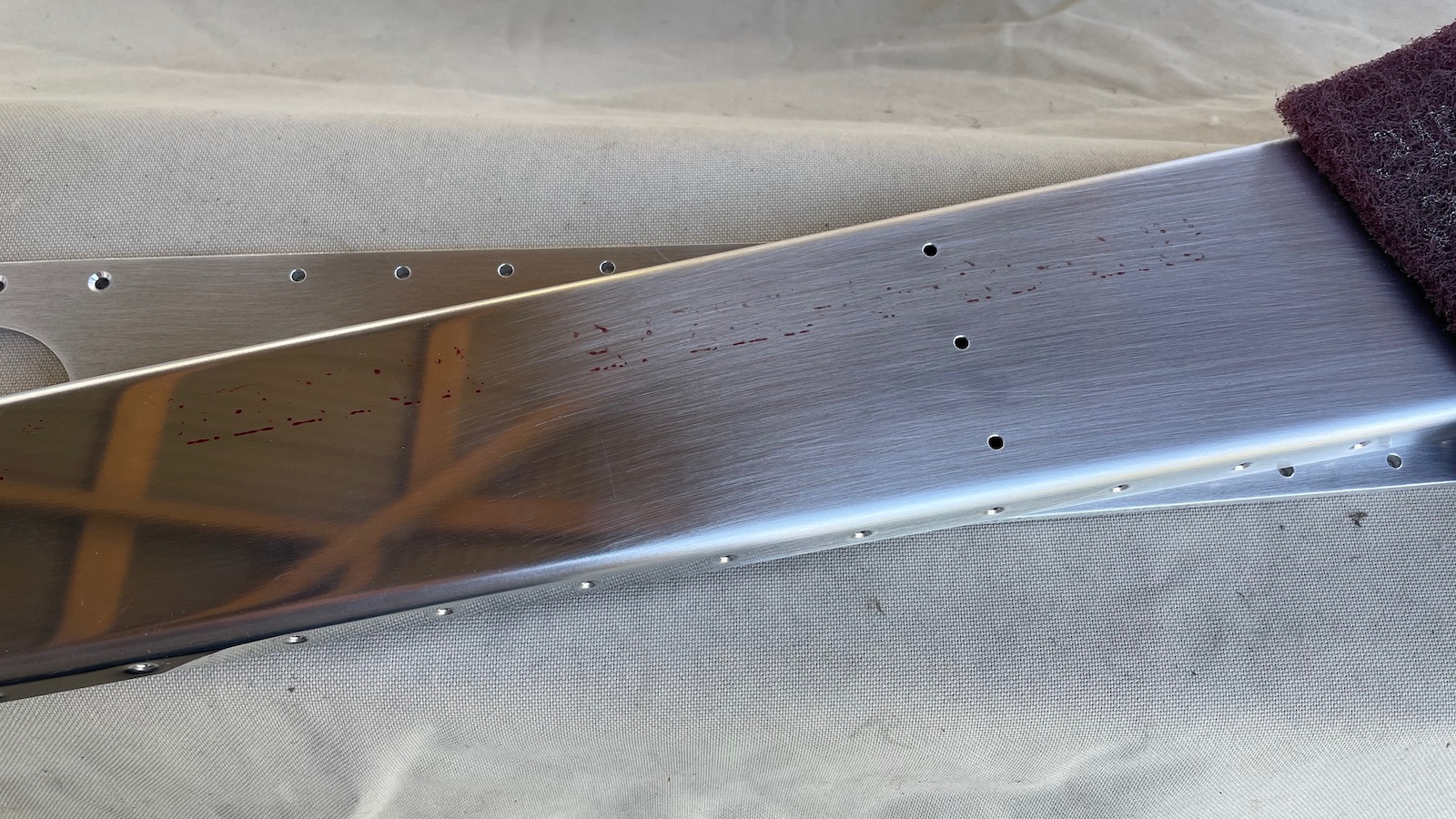

Before priming, each part has to be scuffed up to remove the corrosion-resistant alclad coating to make the paint adhere better. It turns nice shiny aluminum parts into dull, scratchy ones!

The skin was a bit tough to do, as it’s hard to get the spray gun close enough to the bend. This time the skin didn’t turn out too well. I think it was a combination of the way I had the gun set and the aforementioned distance. But, nobody sees the inside!