Today we started work on the rudder, which is the control surface responsible for motion about the yaw axis. It works primarily by deflecting air to the lef or right, and you use your rudder pedals in the cockpit to do so. According to the instructions, the rudder and the elevators will probably be the most challenging parts in the empennage assembly.

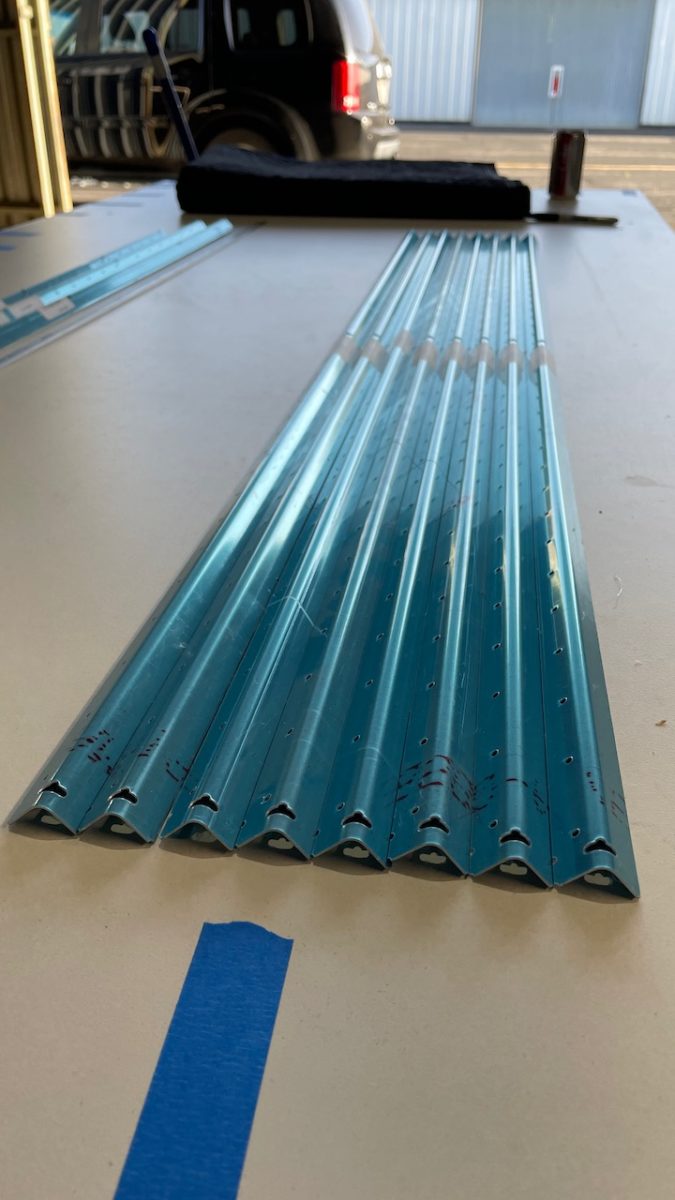

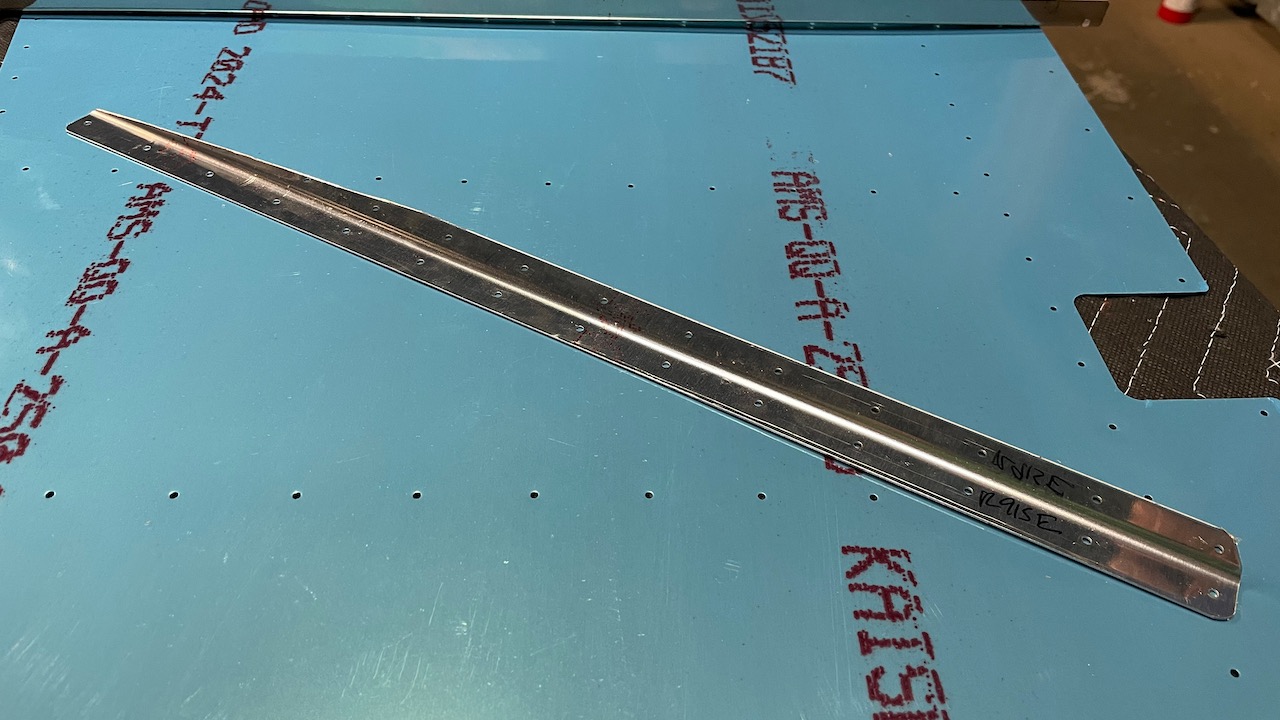

Tonight’s work started off with cutting apart some angle stock in order to form and shape stiffeners for the rudder. The rudder skin is about half the thickness of the stabilizer surfaces, so we have to be careful with them. The stiffeners increase their rigidity. Each stiffener stock part has to be cut in half, then shaped according to the plans. Fortunately, Van’s cut in small reference marks so we know where we have to cut the parts to the exact size.

It didn’t take too much time to do the right side…about 2.5 hours total.We quite enjoy the challenge of fabricating the parts.

Next time we’ll cut down the stiffeners for the left skin. Then we move on to building the skeleton. The rudder and elevators have a heavy lead counterweight that helps with control forces while flying. They look pretty neat. You’ll see them in the next couple sessions.