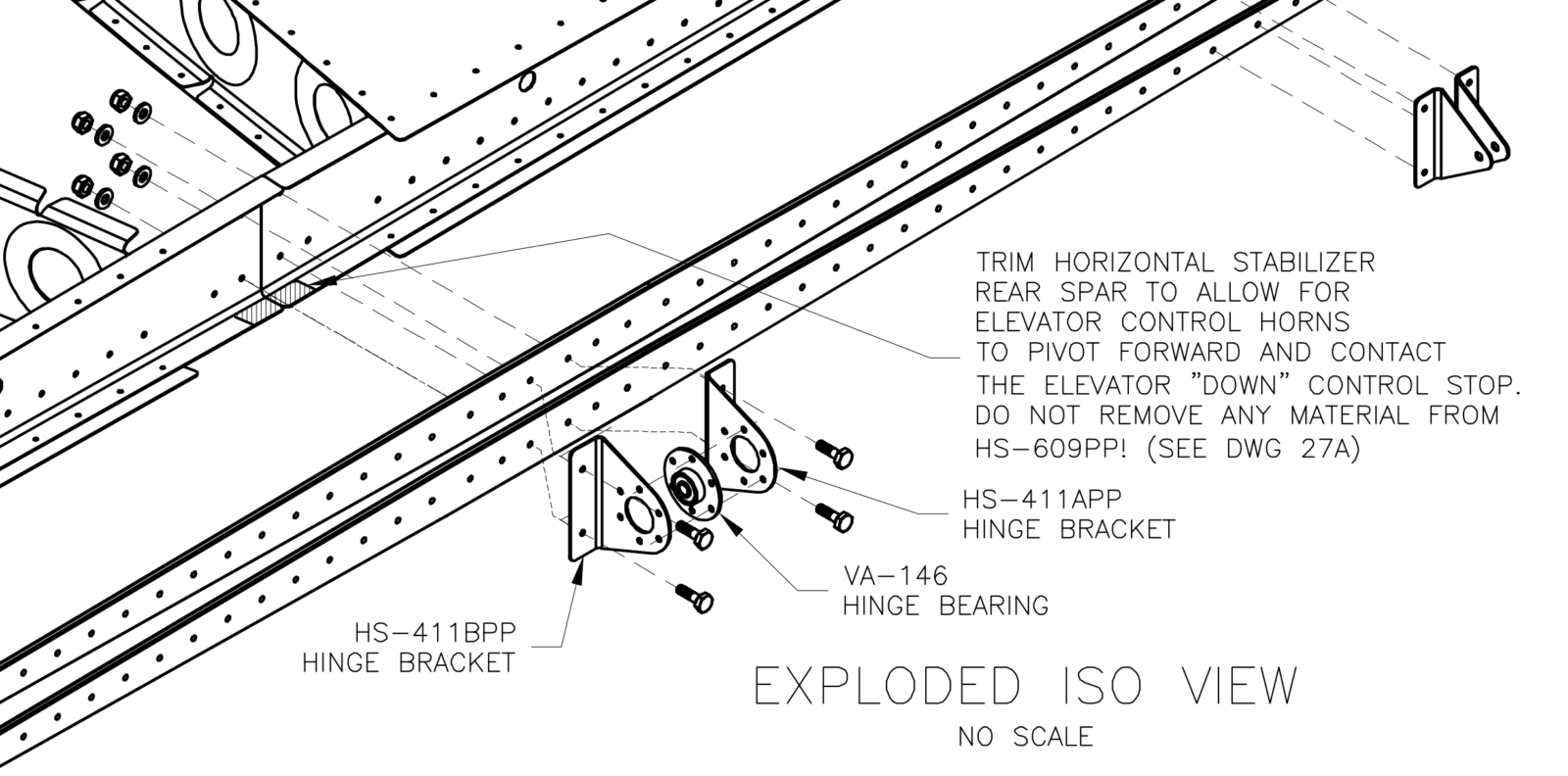

Early on in the process, I noticed this note on the plans, which calls for trimming a couple notches out of the rear spars in order to give the elevator horns enough room to move to their bottom stops. This wasn’t called out in the instructions at all, but I made a mental note to make sure I cut them out before priming.

Well, guess what happened?

I dropped Van’s an email and asked if I should do this trimming now, or if I could wait until I actually got the elevator horns (which were on back order initially) installed in a later step. They suggested that it’s best to cut the nothes now, since damaging the 609PPs in any way would be a bad thing. Since the notches come close to the bars, it was prudent to cut them out before we started riveting.

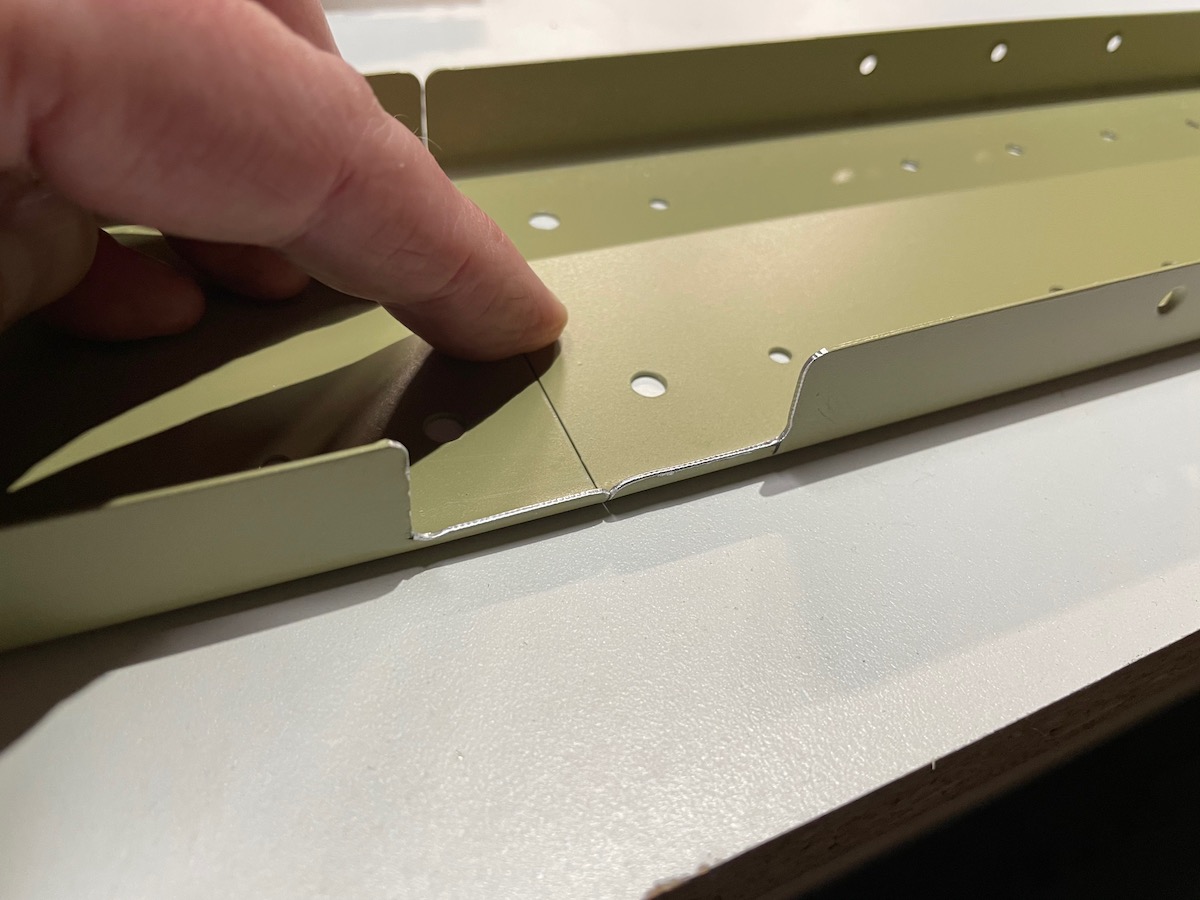

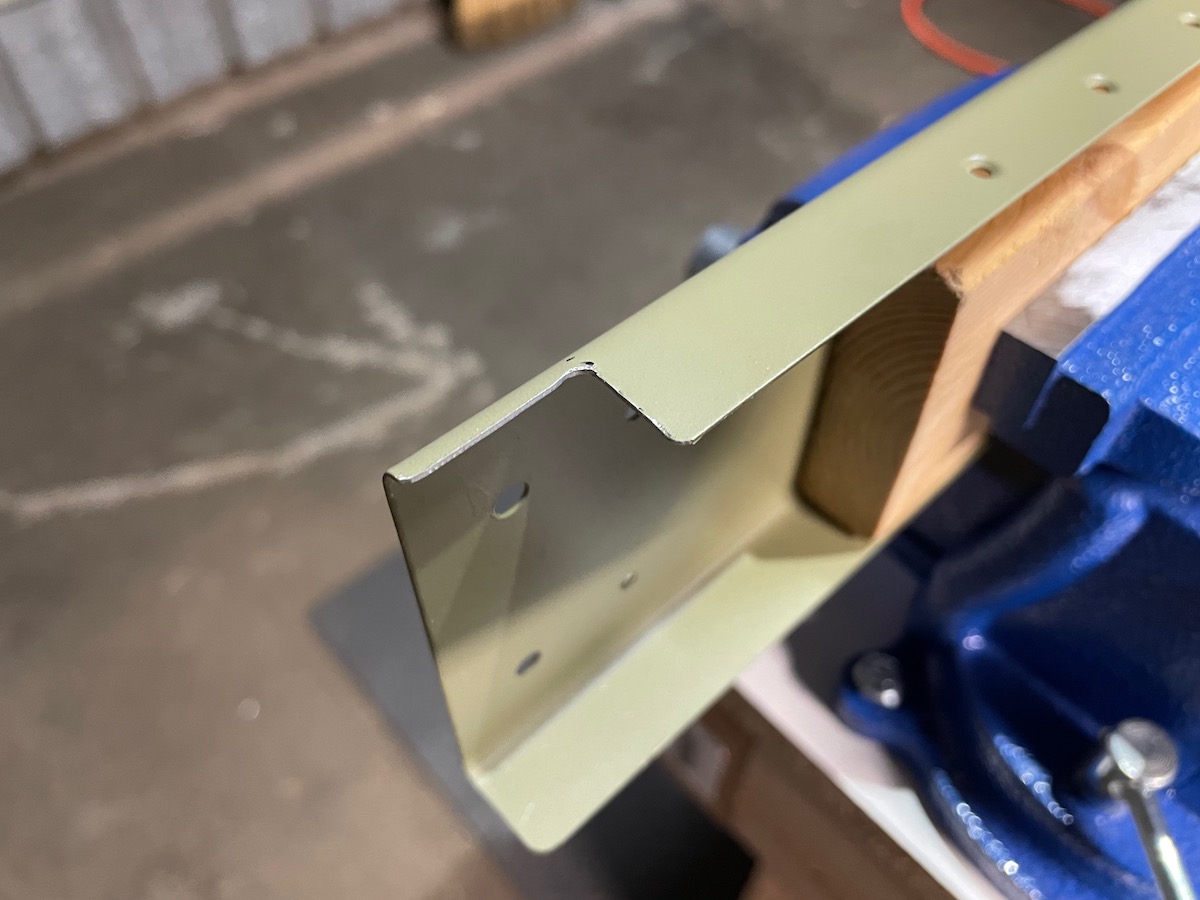

I’ve been dreading this step because the last time I had to cut a large-diameter hole I made a mess of it (didn’t practice at all with the step drill). Also, I didn’t feel I had the proper tools for cutting the notches out. So, I swung by Harbor Freight and picked up a pair of air shears after watching a number of YouTube videos about them. After a few tries, I committed to doing it.

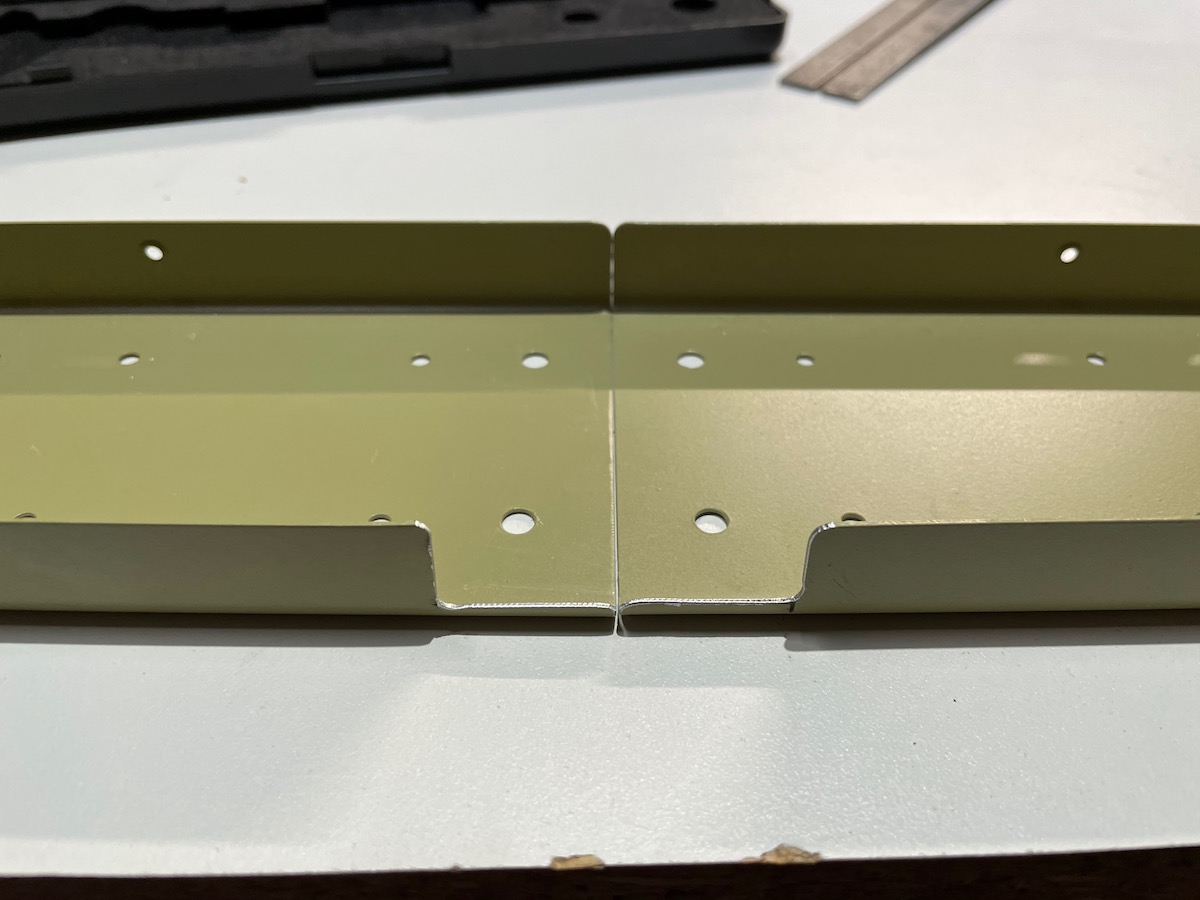

In retrospect, I should have lined the spars up first and drew the lower line across both. I marked them up separately, so they’re not even. It’s not a bad thing, just an O/C thing. 🙂

One of the other RV builders at the airport dropped by, and I showed him my conundrum. He thought maybe I was overthinking the issue, and I agree. It all ended up fine. Build on!