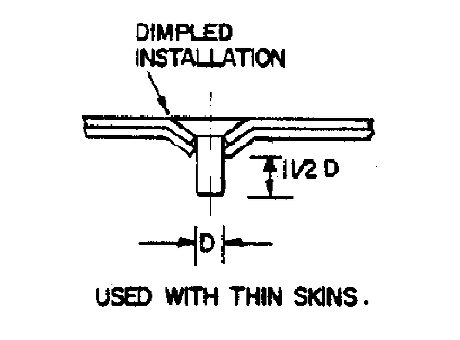

We brought home all the pieces of the horizontal stabilizer that needed to be dimpled so that we could do it from the comfort of the couch! Dimpling is the process of forming dimples in the metal so that they can accept a flush rivet. The fact that it’s a “flush” rivet means it sits flush against the skin, and so it needs a dimple to nestle into.

Not only do you have to dimple the skins, but anything underneath the skin that will end up riveted together.

There are a lot of different ways to dimple using a variety of tools. The most convenient and quickest is to use a hand squeezer, which I’ve shown in past posts. That’s the tool we brought back to do the dimpling for these pieces.

Here’s a short video clip of me dimpling one of the hstab ribs. I love the crinkling sound the metal makes as the dimple is formed. It’s relaxing!

All those parts in the background will require dimpling. We’ll do the skins at the hangar, since we need to use the c-clamp dimpler for those.

I’ll be borrowing a pneumatic dimpler from a friend to make this process a little faster and less wearing on the forearm muscles. I’d buy one, but I can’t justify the $800-900 they cost. Besides, you have to be around the compressor, which is not only loud, but a pain in the butt to haul back and forth from the hangar should we want to continue dimpling from the couch.

Pingback: Homepage