The next day at the hangar we continued working where we left off with the horizontal stabilizer rear spar. Next up was to attach the brackets to the spar, which would be mount points for the elevator…the flight surface that pivots up and down, which raises and lowers the nose during flight.

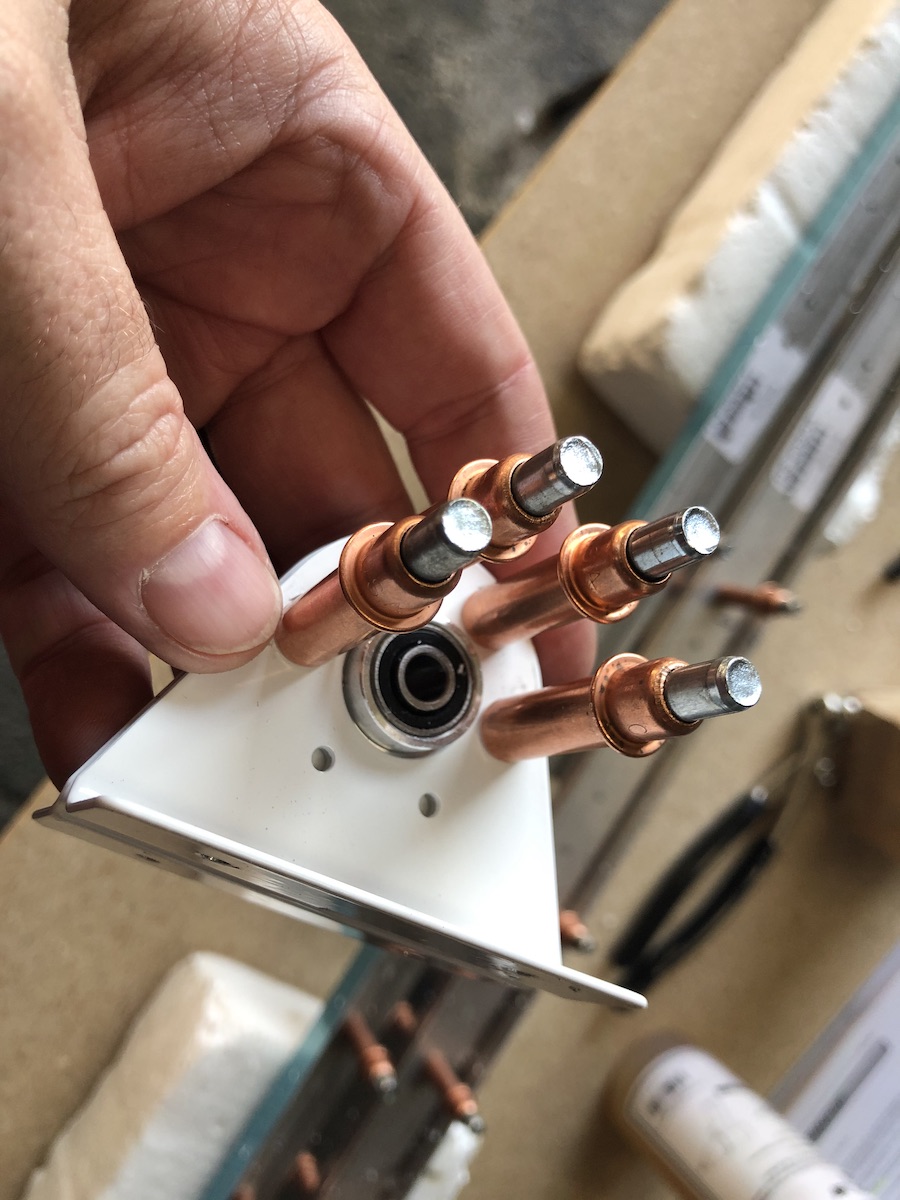

There are 5 brackets that we need to attach, and the middle one also has a bearing in it. The bearing is sandwhiched inbetween to brackets, and the first thing we needed to do was to match drill through the brackets and rivet the assembly. This was the first riveting we’ve done on the actual plane!

The brackets came primed already, which is why they’re white. Once the 6 holes were drilled through, it was riveting time! I hand-squeezed the 6 AN470 rivets into place. It turned out pretty well!

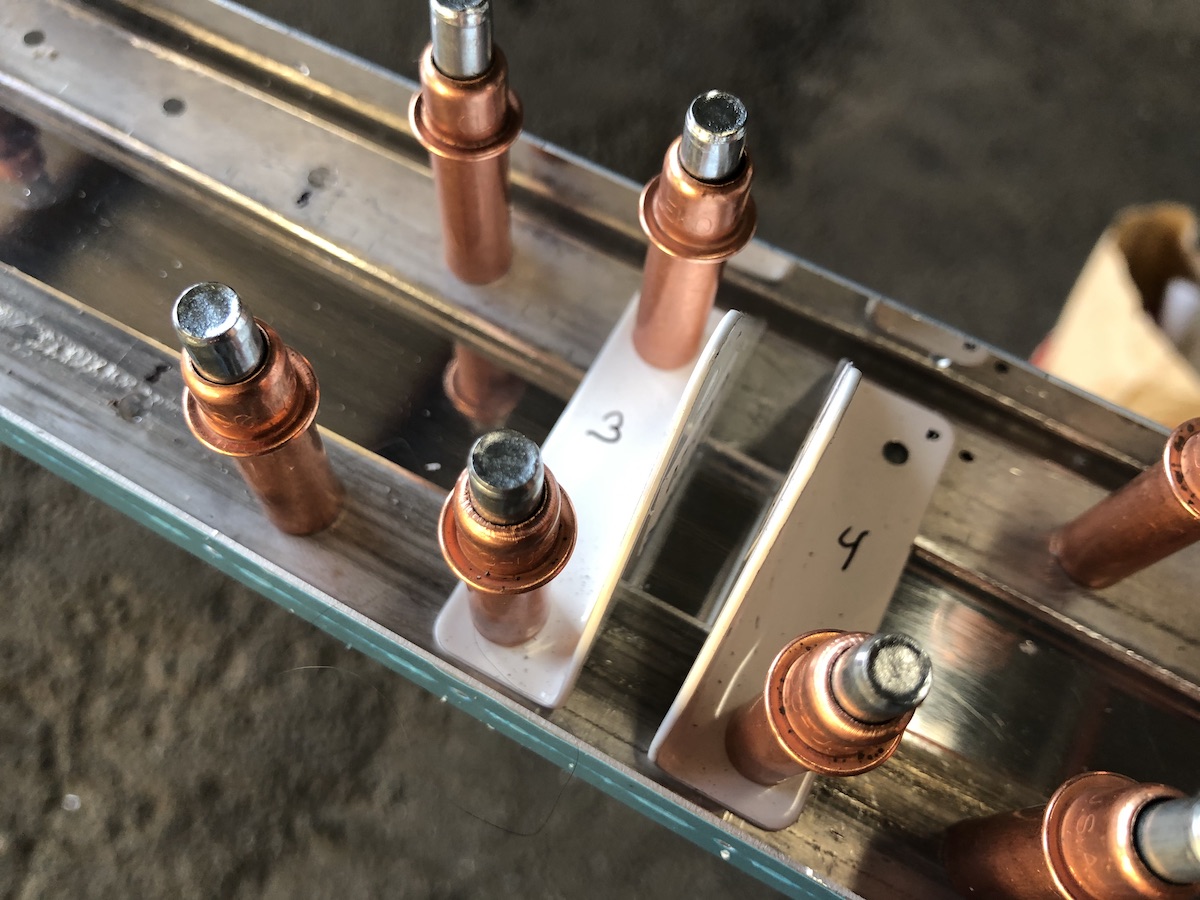

The other brackets didn’t have bearings, so they were just match-drilled and cleco’ed onto the rear spar.

That was about it for this session. We logged another 2.5 hours onto our EAA Builder’s Log site.