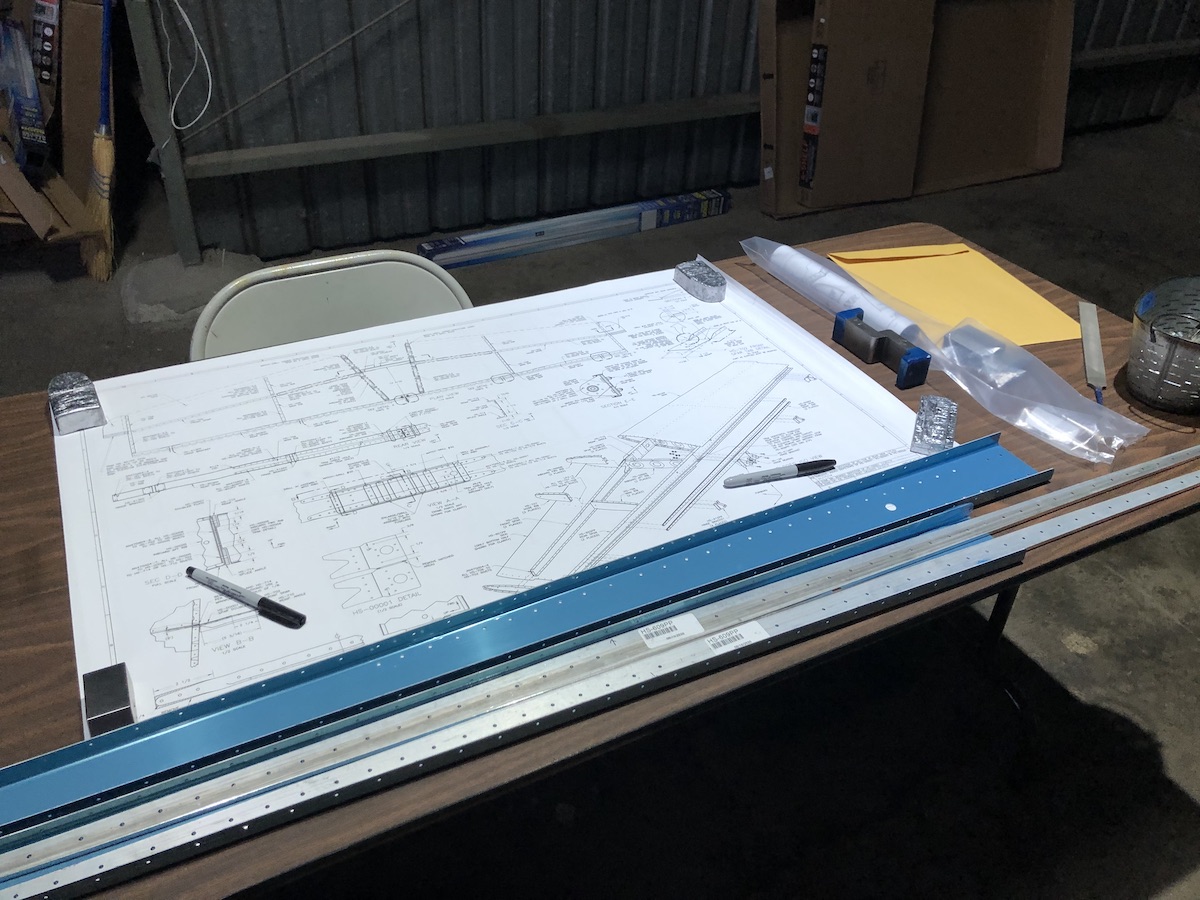

Well it’s here… Day One of the build! We start on the Horizontal Stabilzer Rear Spar, or HaSaRdS! Just kidding. The main activity for this phase is to “break” the 2 long rear spar reinforcing bars. They’re pretty thick, and the edges are sharp, so we have to impart a rounding over to both help them lay flat inside of the spar (which has rounded bends), and also to not cause pressure points which could lead to cracks. This is a common theme throughout the build: deburring, or smoothing over the rough edges of parts that will have contact points.

There are a number of ways to skin this cat. Since we were just getting started, and not everything was set up, we decided to go old school and use a couple files to round over all the edges. I cut out a small 1/8″ diameter gauge, since that’s what the instrcutions called for. We filed until the gauge fit, then we ran the edges against a small Scotch Bright Cut and Polish wheel mounted in the drill press. This gave a nice, smooth and satiny finish to the parts, and allowed them to nestle into the spar flatly.

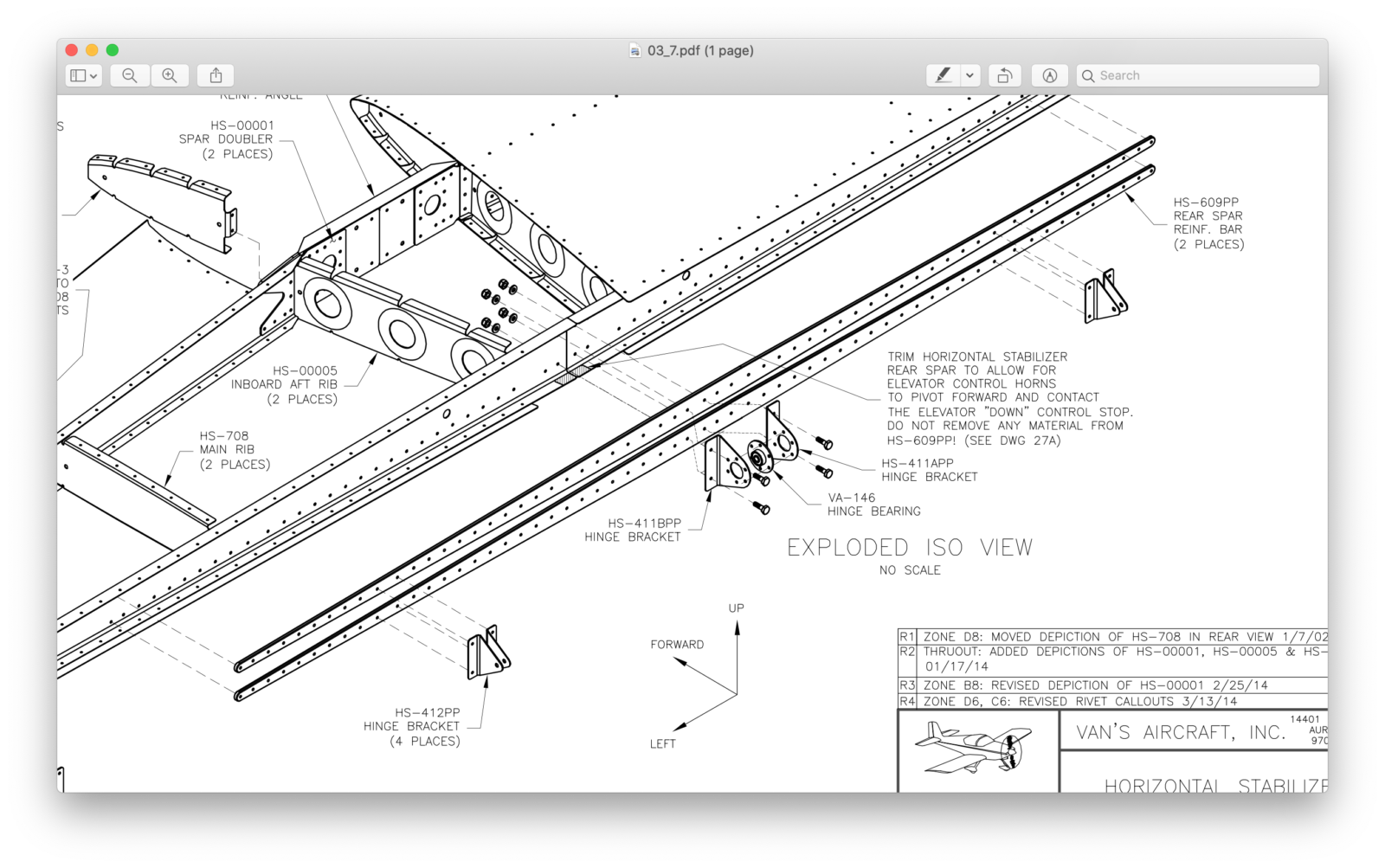

Once the reinforcing bars were done, we cleco’ed them to the 2 spar pieces, and “match drilled” the holes. Vans hole punches the parts a little smaller than the finished size, so we as builders have to drill the holes up to the size for the rivets. We’re using 3 types of rivets in the project: AN346AD, AN370AD and some blind rivets (also known as “pop” rivets).

Clecos are special clamps that you insert into holes in two or more pieces to hold them together. The general workflow is to prepare the pieces, cleco and match-drill them, then take them all apart, deburr the holes and edges, prime the parts, then rivet them together.

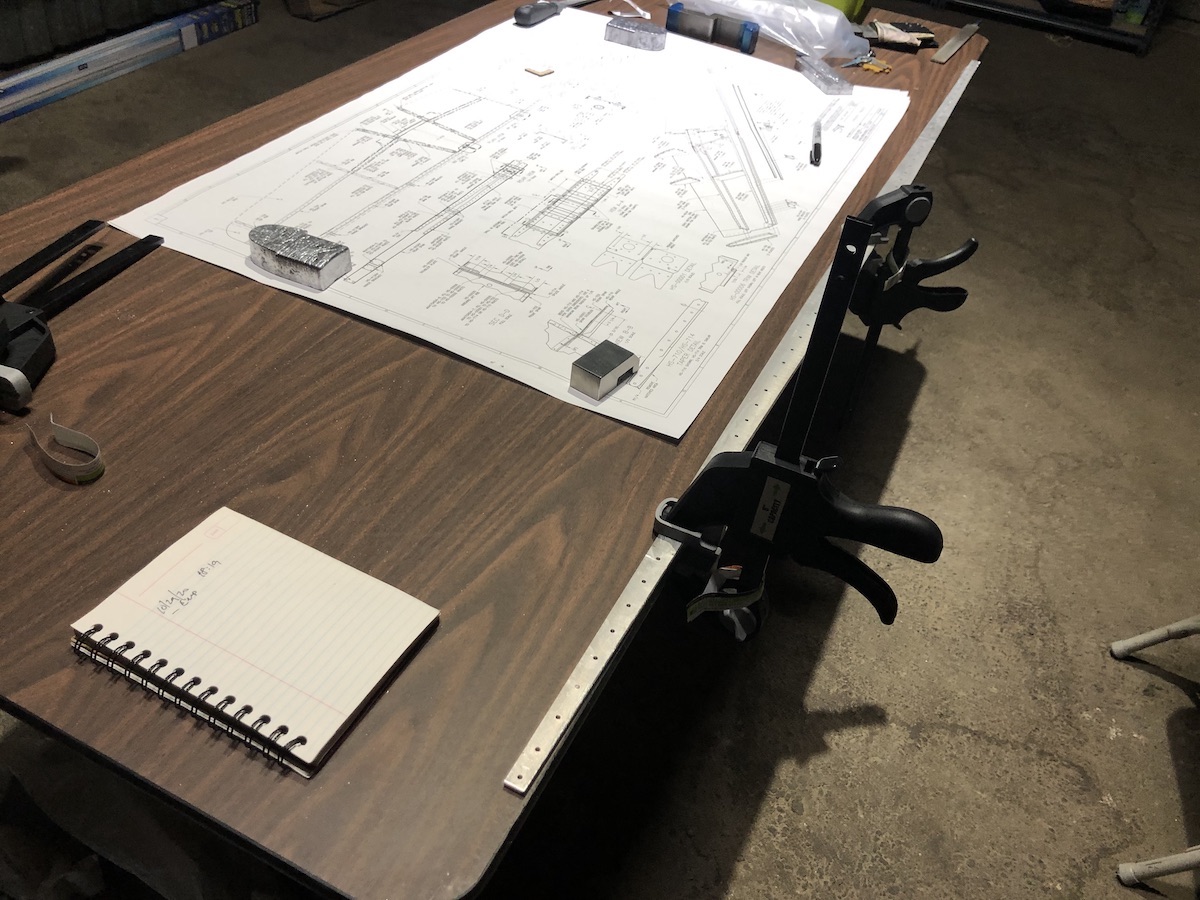

So went day 1! We spent 2.5 hours working on this part of the tail feathers. It was challenging, but really fun to do together!