I’ve been looking at printers for a while now, and after “inheriting” the Makerbot Replicator 2X from work, I was really excited about buying one for myself. Initially I was interested in the Printrbot Simple Metal from Adafruit, but they’ve been out of stock.

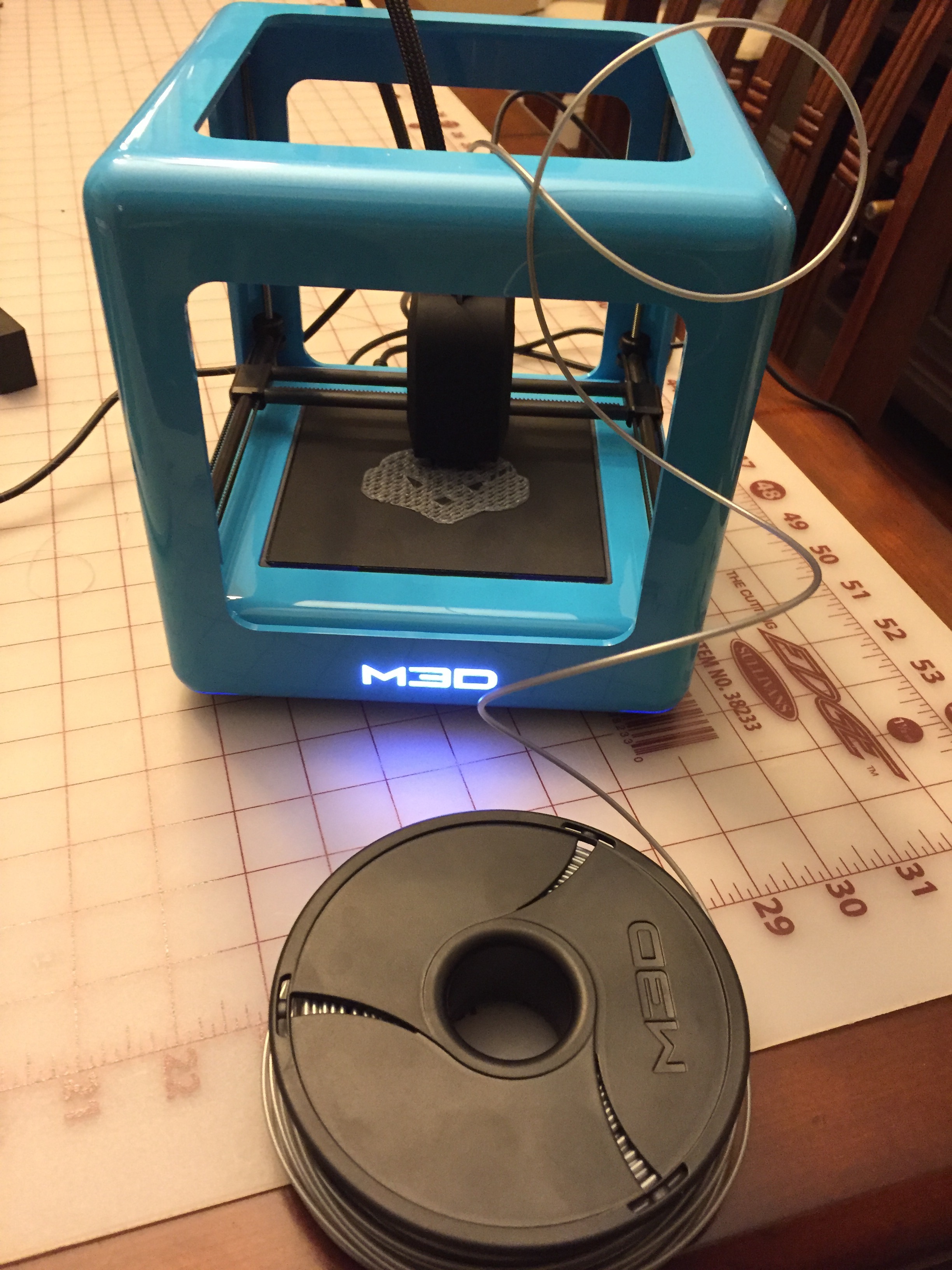

Then I came across the Micro 3D printer, a small and lightweight indie project that was currently shipping. After checking out a few reviews and YouTube videos, I decided to buy it for $349.

The printer is tiny! It’s about 8″ square. The filament spool actually sites under the print bed, making for a very compact arrangement. It’s also quite quiet, making watching the printer make it’s prints on the dining room table just dandy.

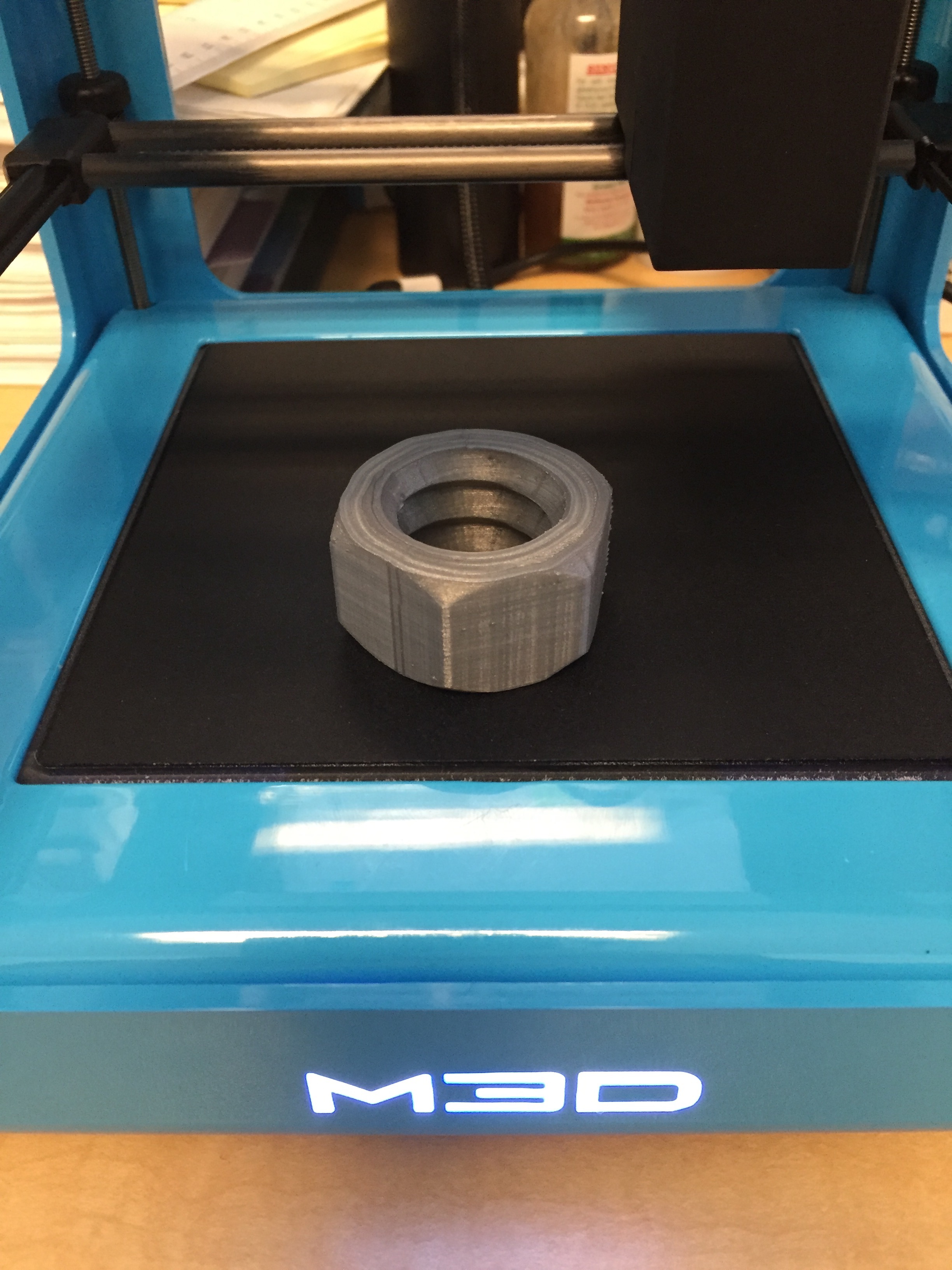

So I’ve been printing several things from Thingiverse lately, and it’s been fun. This huge nut took about an hour and 15 minutes to print, and as it turns out, fits on my ring finger just fine. 🙂 Next up is the accompanying big bolt!

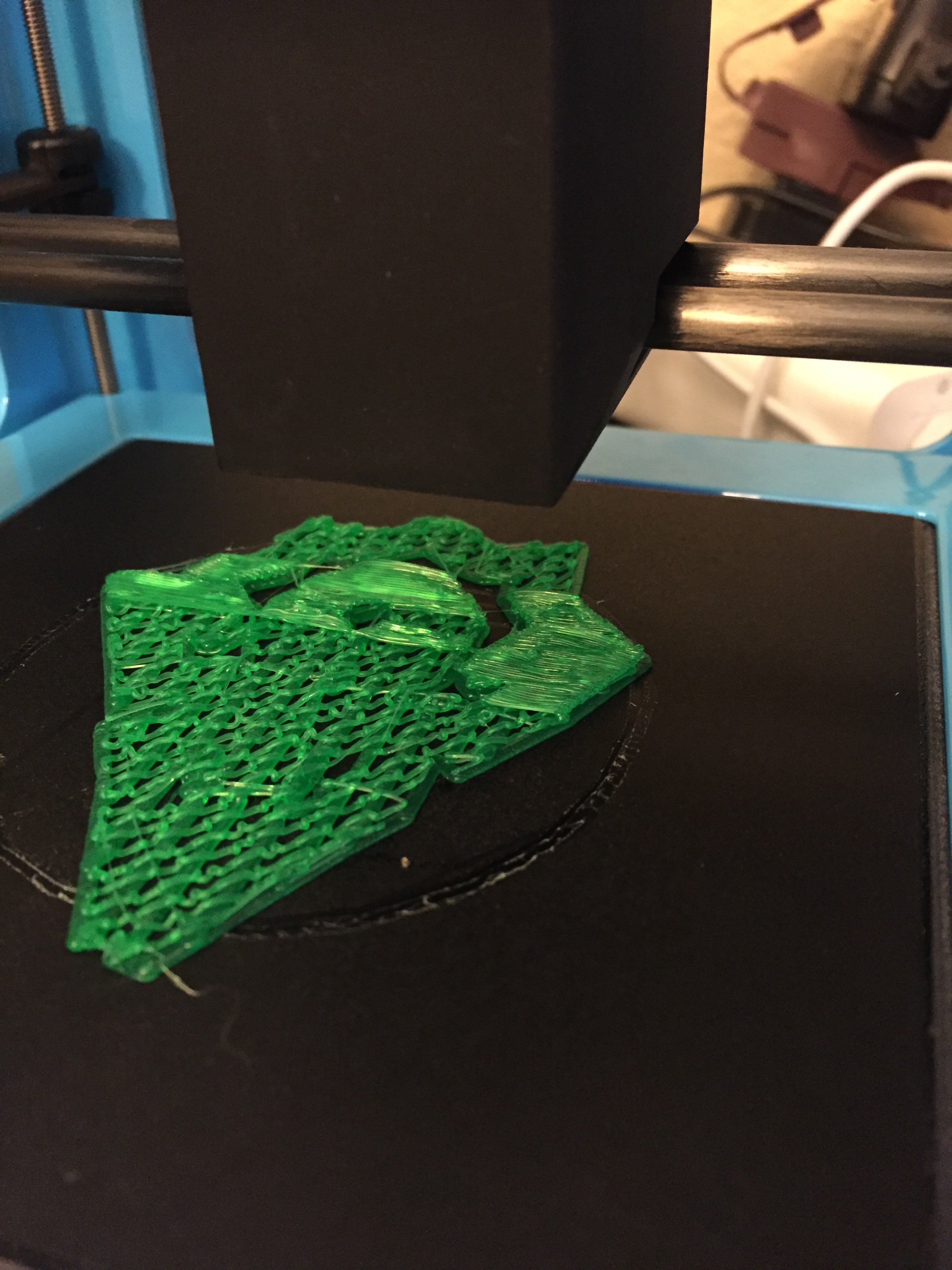

The largest thing by far was this green dragon, which took the better part of 7 hours to print, due to the detail. I broke his front paw off when I was releasing him from the print raft, but still it’s pretty cool.

This is prior to cleanup. The filament is brass, and evidently has actual brass infused. Very shiny.

Print Server

So pretty shortly after discovering the printer, I found out about an open source print server that I could run on my Raspberry Pi. It’s called OctoPrint. The UI is great, and theoretically had all the functionality I needed to use it with the M3D. So of course I downloaded it and burned a quick SD card for the Pi.

The concept is awesome. OctoPrint is a web-based print server you can upload your 3D files to, set the parameters, view how it looks on your printer, then submit the job to the local Slicer process to begin slicing it up and printing it.

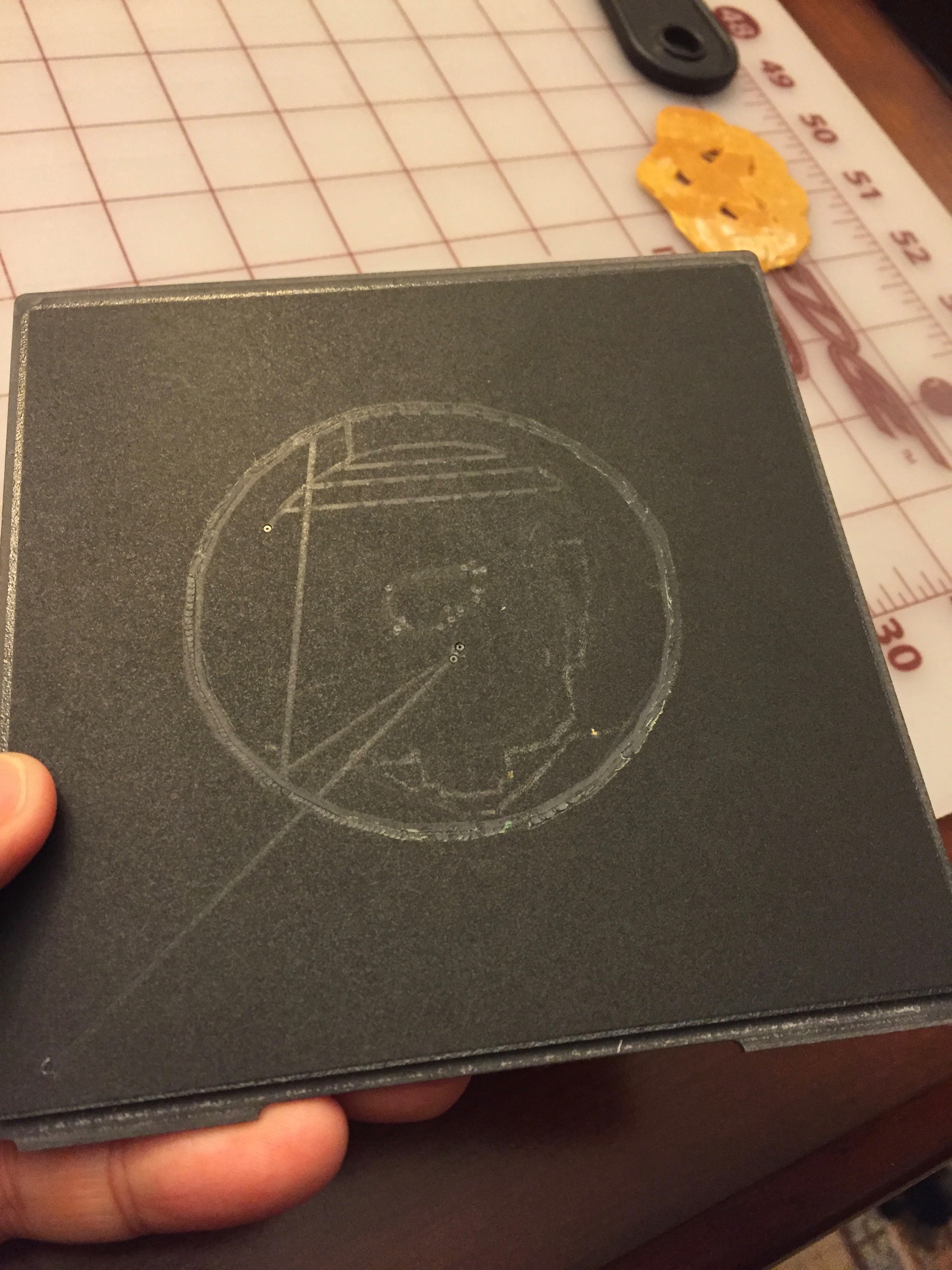

Unfortunately, OctoPrint isn’t quite ready for prime-time, at least not with the M3D. I’ve experienced some “incidents” while using it. Fortunately the printer wasn’t damaged. It appears that the calibration routines are a bit off. After calibrating the print head dug into the BuildTak cover on the print bed, leaving furrows where the first layers of the piece should have been. Also, there are several holes where the extruder head was pushed down into the tape.

This clearly shouldn’t have happened. I’m glad I ordered a 3-pack of BuildTak! Another weird thing that happened is that part of a raft didn’t adhere to the rest, leaving a “bubble” that raised above the rest of the raft. I noticed it because the extruder fan was rubbing against it as the extruder moved back and forth, making a loud “buzzzzz!’

So for now, I’m back to using the included software, which is the best, especially on the Mac (it uses the Mono framework, so the devs didn’t really spend the time to make a native app, they just ported over their windows one).

There is another print spooler I’ll probably try because I like the idea of leaving the printer run unattended. Both have the ability to attach a webcam (which I have for the Pi) so you can monitor the status of the print! Very cool.